INSTALLATION GUIDE

Cast Aluminium Brackets For Truck Mudguards

IMPORTANT MOUNTING INFORMATION:

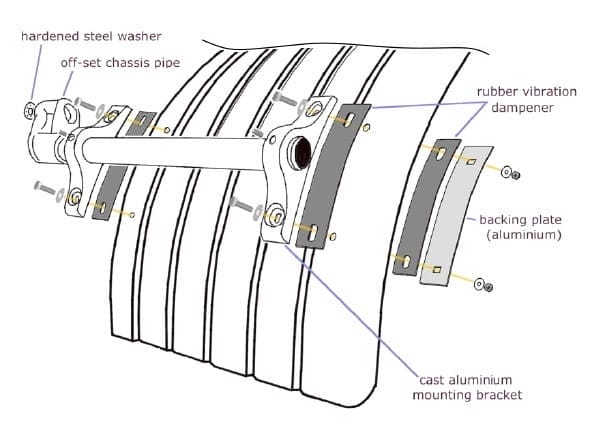

- The LELOX off-set chassis pipe (OSCP) includes a hardened steel washer which must be mounted between the chassis pipe base and truck/trailer chassis. The bolt used should be at least Grade 8.

This washer must be fully seated on the end of the chassis pipe cast aluminium base, otherwise the pipe may not be seated properly when the bolt it tightened (i.e. the washer sitting partly on the shoulder of the base).

We recommend that you leave the tape securing the washer to the base of the chassis pipe in place, cut a hole in the tape so that your bolt can go through the base. Remove the tape only after the bolt has been fully tightened, securing the chassis pipe in place.

- If the chassis pipe is not attached to a double-thickness of chassis, a thick steel washer of at least 10-12 mm thickness and 75-80 mm diameter should be used on the inside of the chassis. This will reduce the likelihood of the pipe loosening up over time (by warping of the chassis).

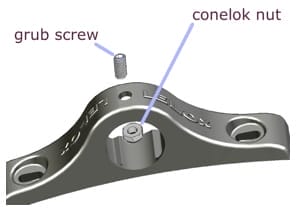

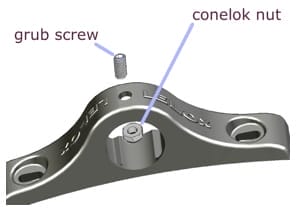

- The short recessed grub screw at the top of the cast aluminium mounting bracket (MMAB or PMAB if mounted on a plastic mudguard) should be tightened onto the chassis pipe with the supplied ‘Conelok’ nut to avoid movement of the mudguard on the chassis pipe.

Cast Aluminium Brackets For Truck Mudguards

IMPORTANT MOUNTING INFORMATION:

-

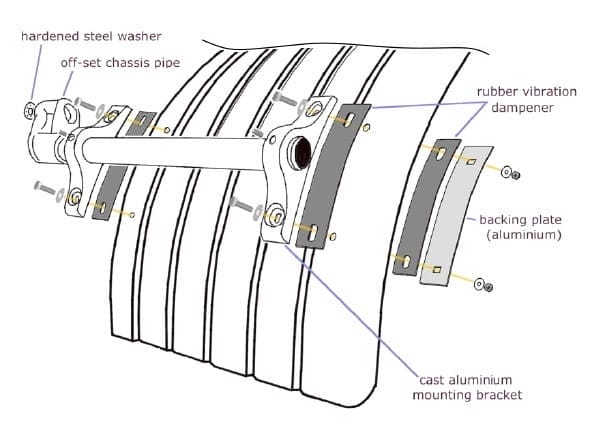

The LELOX off-set chassis pipe (OSCP) includes a hardened steel washer which must be mounted between the chassis pipe base and truck/trailer chassis. The bolt used should be at least Grade 8.

This washer must be fully seated on the end of the chassis pipe cast aluminium base, otherwise the pipe may not be seated properly when the bolt it tightened (i.e. the washer sitting partly on the shoulder of the base).

We recommend that you leave the tape securing the washer to the base of the chassis pipe in place, cut a hole in the tape so that your bolt can go through the base. Remove the tape only after the bolt has been fully tightened, securing the chassis pipe in place. -

If the chassis pipe is not attached to a double-thickness of chassis, a thick steel washer of at least 10-12 mm thickness and 75-80 mm diameter should be used on the inside of the chassis.

This will reduce the likelihood of the pipe loosening up over time (by warping of the chassis). - The short recessed grub screw at the top of the cast aluminium mounting bracket (MMAB or PMAB if mounted on a plastic mudguard) should be tightened onto the chassis pipe with the supplied ‘Conelok’ nut to avoid movement of the mudguard on the chassis pipe.

Step-by-step Guide to Mount mudguards on a Truck/Trailer

IMPORTANT: IF YOU HAVE ANY DOUBTS WHATSOEVER ABOUT YOUR ABILITY TO MOUNT MUDGUARDS ON YOUR TRUCK OR TRAILER – STOP!

NOTE: These instructions are a guide only – they do not take into consideration issues or problems that you may be faced with. We accept no liability for any adverse results you may get using these instructions.

Park truck/trailer on flat level ground.

If truck/trailer has air-bag suspension, dump the air from the suspension so that the truck/trailer rests on the bump stops.

Remove mudguard from wrapping, leaving protective film in place. Put mudguard on wheel/tyre.

Put spacer/s between mudguard and tyre – this will give you the minimum clearance between mudguard and tyre. For sprung suspensions, the spacing will need to be at least equal to the suspension travel available between current axle position and the bump stop. This is done so that the tyre will not rub against the mudguard under maximum suspension loading.

Repeat steps 3 and 4 for any other mudguard/s on that side of truck/trailer.

Step back from truck and make sure that the mudguard/s are level and centrally positioned on the tyres, adjust as necessary. The bottom edges of the mudguard should be horizontal and the bottoms of the mudguards should line-up between multiple axles when your suspension will be at its normal operating level. Make sure that the mudguard will not foul with any running gear, trailers etc.

Decide where you want to put the brackets on the mudguard – this may depend on where you can pick up existing holes on the truck/trailer frame that can be used to attach the off-set chassis pipes. Many people position the chassis pipe roughly 400-600 mm up from the bottom edge of the mudguard – the exact position will depend on where the chassis pipe can be attached to the truck/trailer frame.

Select existing bolt hole on truck/trailer chassis where you will mount the off-set chassis pipe. Remove bolt from frame and loosely attach the off-set chassis pipe (part no: OSCP) to the truck/trailer frame (using suitably sized bolts that are a minimum of UNC Grade 8). The off-set chassis pole bolt should be tight enough so that the pipe is horizontal but just loose enough to be able to rotate.

NOTE: the chassis pipe should be bolted through either a double thickness of chassis/frame or else a large thick steel washer (75-80 mm diameter and 10-12 mm thickness) should be used on the inside of the truck/trailer frame/chassis. This is to reduce the likelihood of the pipe loosening over time by warping of the chassis/frame.

Remove Lelox cast aluminium brackets (part no: MMAB for metal mudguards, and part no: PMAB for plastic mudguards) from packaging and put 2 brackets on each chassis pipe.

Rotate chassis pipe so that both brackets sits comfortably against the mudguard, then tighten chassis pipe bolt so that the long tube sits horizontally (when looking from front/rear) and will not move/rotate – final tightening of the off-set chassis pipe can be done as the last step in the installation.

Repeat steps 9 and 10 with the chassis pipe on the other side of the mudguard so that both chassis pipes are in what will be their final position and the brackets are resting comfortably on the face of the mudguard without any pressure onto, or distortion of, the mudguard.

Position the brackets (2 per chassis pipe) on the chassis pipe tube so that they are in the position where they will be mounted – most people position the brackets symmetrically on the mudguard toward the edges. We encourage you to mount the brackets on the flat section near the outer edges of metal mudguards.

Make sure that the bracket is centred on the flat section between the ribs on the mudguard or between the outer rib and the edge (as shown above) – the aim is to drill holes in the middle of the gap between the ribs/grooves/outer edge on the mudguard. The backing plate of the bracket is designed to sit between the ribs/grooves on the inside of the mudguard.

Mark the position of the holes to be drilled. Lelox cast aluminium brackets (part nos. MMAB and PMAB) have 185 mm hole centres, you can use the bracket backing plate as a template to make sure that the holes line up correctly.

Repeat step 14 for the other chassis pipe.

Remove mudguard from truck and drill holes (suggested minimum hole diameter = 12.7 mm) at the points marked on the mudguard (8 holes in total per mudguard). You will need to drill a pilot hole first in metal mudguards – this reduces the chance of a large drill bit slipping and damaging the metal surface.

Attach mounting brackets to the mudguard using the nuts, bolts and washers provided as per the instruction sheet supplied with each bracket – the grub screw and ConeLok nut will be used later to secure the bracket to the chassis pipe. Make sure that the public face of all brackets (i.e. side without the ridges/grooves) is positioned such that they will be facing away from the truck when the mudguard is mounted.

IMPORTANT NOTE: warranty is voided on Lelox metal mudguards if Lelox cast aluminium brackets (part no: MMAB) are not used with the supplied vibrations dampeners to sandwich the mudguard between the bracket and the backing plate.

Return mudguard with brackets attached to the truck/trailer, remove any spacers that may be on the tyre and slide the brackets back onto the chassis pipe so that the mudguard is supported by the chassis pipes.

Make final positioning adjustments so that the mudguard sits symmetrically on the tyre (i.e. same clearance between mudguard on body side and outer side of tyres.

Insert ConeLok nut in the space provided at the top of the bracket and put grub screw through hole in top of bracket so that it goes into the ConeLok nut. Tighten the grub screw using a hex-head wrench or Allen key so that the bracket and mudguard are securely attached to the chassis tube. Repeat for the other brackets.

Repeat steps 7 through 20 for the other mudguards.

Tighten the chassis pipe bolts – use maximum torque setting recommended by the nut and bolt supplier. NOTE: nut and bolt should be at least Grade 8.

Repeat this process for the other side of the truck/trailer. When doing the other side of the truck/trailer refer to the completed side so that there is symmetry in the final result.

Remove protective plastic film from metal mudguards and you are done!

IMPORTANT NOTE: These instructions are a guide only – they do not take into consideration issues or problems that you may be faced with. We accept no liability for any adverse results you may get using these instructions.